Understanding Aluminum Welding in Chester County, PA

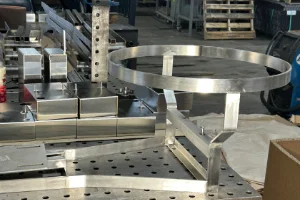

At Tigworx, we specialize in aluminum welding in Chester County, PA, delivering precision and durability for industries that demand the highest standards. Aluminum is valued for its strength-to-weight ratio and natural resistance to corrosion, but welding it requires expertise that goes beyond standard techniques. Its lower melting point and high thermal conductivity mean heat dissipates quickly, making accurate control essential to avoid burn-through or distortion. On top of that, aluminum’s protective oxide layer must be properly cleaned and disrupted to achieve a clean, reliable bond. Our team at Tigworx overcomes these challenges using advanced TIG (Gas Tungsten Arc) welding, which provides unmatched control over heat input and weld quality. The result is a smooth, strong, and contamination-free joint—perfect for projects where precision and performance matter most.

At Tigworx, we specialize in aluminum welding in Chester County, PA, delivering precision and durability for industries that demand the highest standards. Aluminum is valued for its strength-to-weight ratio and natural resistance to corrosion, but welding it requires expertise that goes beyond standard techniques. Its lower melting point and high thermal conductivity mean heat dissipates quickly, making accurate control essential to avoid burn-through or distortion. On top of that, aluminum’s protective oxide layer must be properly cleaned and disrupted to achieve a clean, reliable bond. Our team at Tigworx overcomes these challenges using advanced TIG (Gas Tungsten Arc) welding, which provides unmatched control over heat input and weld quality. The result is a smooth, strong, and contamination-free joint—perfect for projects where precision and performance matter most.

Applications of Aluminum Welding

The versatility and benefits of welded aluminum components make them indispensable across a wide spectrum of applications. In the marine industry, aluminum welding is crucial for fabricating lightweight boat hulls, railings, and structural components that benefit from corrosion resistance in saltwater environments. The automotive sector utilizes aluminum for chassis parts, engine components, and custom vehicle modifications, where reducing weight directly translates to improved fuel efficiency and performance. Architectural projects often feature aluminum for its aesthetic appeal and durability in facades, railings, and various structural elements. Industrial settings rely on aluminum for manufacturing enclosures, machine frames, and specialized equipment where a combination of strength, light weight, and corrosion resistance is vital. Our capabilities extend to custom fabrication, supporting innovations and specific project needs across these and other sectors.

Get a Free Quote

The Tigworx Advantage

Choosing Tigworx for your aluminum welding in Chester County, PA needs means partnering with a team that prioritizes technical excellence and a thorough understanding of your project’s demands. Our advantage stems from our specialized focus and the methodical application of best practices in welding aluminum. We are not simply joining metals; we are ensuring the long-term performance and integrity of your components. Our technicians possess not only the manual dexterity required for intricate welding but also the knowledge to anticipate and mitigate potential issues inherent in working with aluminum. This deep expertise translates into consistent, high-quality results that you can depend on, project after project. We believe in delivering products that meet both functional and aesthetic standards.

Get a Free Quote

Working With Tigworx

Engaging with Tigworx for your aluminum welding project is a straightforward process designed to ensure clarity and satisfactory outcomes. It typically begins with a detailed discussion to understand the specific requirements, intended application, and any particular challenges associated with your components. We review drawings, material specifications, and project timelines to ensure alignment. Our team then develops a plan for execution, selecting the appropriate welding techniques and quality control measures. Throughout the fabrication process, we maintain open communication, providing updates and addressing any questions that may arise. Upon completion, each welded part undergoes careful inspection to verify its integrity and adherence to specifications before delivery. Our aim is to provide a reliable service that seamlessly integrates with your project’s needs, from initial concept to final component delivery.

Ask a Question

Areas We Frequently Serve

- Chester County, PA

- Downingtown, PA

- Eagle, PA

- Exton, PA

- Honey Brook, PA

- Malvern, PA

- Paoli, PA

- Phoenixville, PA

- West Chester, PA